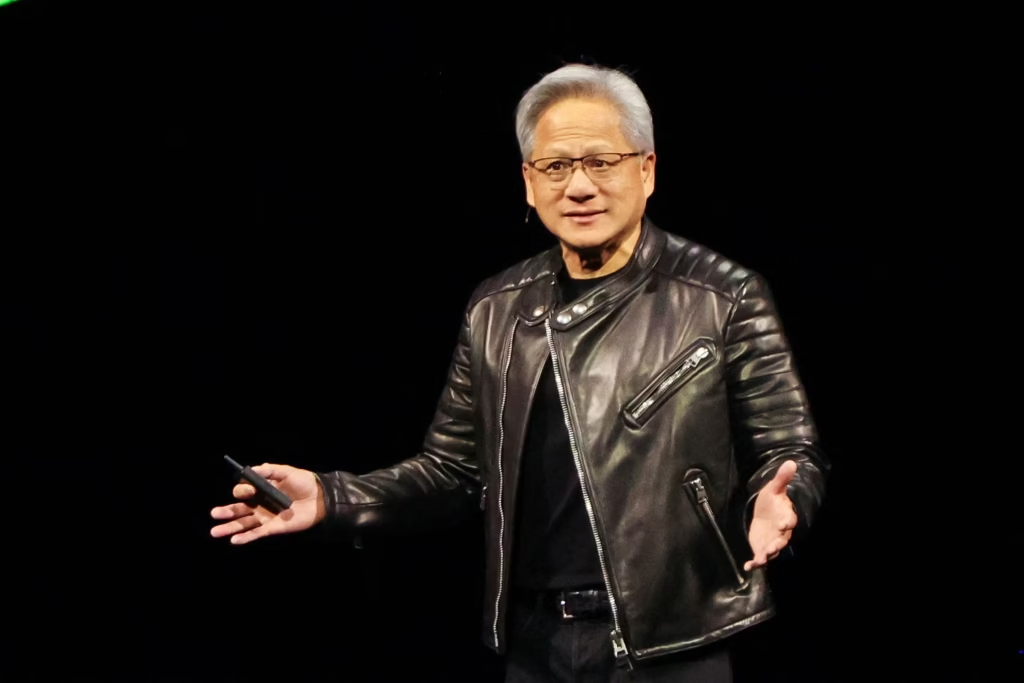

Nvidia CEO Jensen Huang has recently projected that humanoid robots will become prevalent in manufacturing environments within the next five years.

This forecast underscores a significant shift in industrial automation, where robots not only perform repetitive tasks but also collaborate alongside human workers to enhance efficiency and safety.

During Nvidia’s annual developer conference in San Jose, California, Huang highlighted the rapid advancements in artificial intelligence (AI) and robotics. He introduced new software tools designed to facilitate humanoid devices’ navigation and interaction within complex environments, making them more adaptable to dynamic manufacturing settings. Huang emphasized that the integration of such robots is imminent, stating that their widespread adoption is “not a five-years-away problem, this is a few-years-away problem.”

The manufacturing sector is poised to be the initial beneficiary of humanoid devices due to its structured tasks and controlled environments. Huang noted that deploying robots in factories offers clear economic advantages, estimating that the cost of renting a humanoid robot could be around $100,000. This investment is justified by the potential for increased productivity and the ability to perform tasks that may be hazardous to human workers.

The momentum towards integrating humanoid devices into manufacturing is further evidenced by collaborations between technology companies and automotive manufacturers. Mercedes-Benz, for instance, has invested a substantial sum in Apptronik, a Texas-based robotics firm, and is actively testing humanoid robots for tasks such as moving components and conducting quality checks. These trained through teleoperation, are being evaluated at Mercedes-Benz’s facilities in Berlin and Hungary, with plans to expand their use to more sites. The primary goal is to delegate repetitive and hazardous tasks to robots, especially in areas facing labor shortages.

Similarly, BMW has been testing the Figure 02 humanoid on its production lines. Designed for manufacturing and logistics, the Figure 02 represents a significant step towards integrating advanced robotics into industrial processes. These initiatives reflect a broader industry trend towards embracing robotics to enhance operational efficiency and address workforce challenges.

Nvidia’s commitment to advancing AI and robotics is evident in its unveiling of next-generation AI chips, such as the Blackwell Ultra and Vera Rubin. These chips are expected to play a crucial role in the development of more capable and efficient humanoid devices. Huang emphasized that AI has evolved beyond perception and computer vision to encompass generative and agentic AI, capable of reasoning and understanding complex contexts. This evolution paves the way for “physical AI,” where robots can conceptualize interactions involving friction and inertia, making them more adept at performing intricate tasks in manufacturing settings.

To support the development of humanoids, Nvidia introduced the Isaac GR00T N1, an open-source model designed to facilitate the creation of robots capable of navigating and interacting within human-centric environments. Additionally, the company is developing the Cosmos AI model to generate synthetic training data, which is essential for training robots to perform a wide array of tasks without the need for extensive real-world data collection.

The integration of humanoids into manufacturing signifies a transformative period in industrial operations. These are expected to handle tasks that are repetitive, physically demanding, or hazardous, thereby allowing human workers to focus on more complex and strategic activities. This collaboration between humans and them is anticipated to lead to safer work environments, increased productivity, and the creation of new job categories centered around its’ device maintenance and oversight.

However, the widespread adoption of humanoids also presents challenges, including the need for robust safety standards to ensure seamless human-device collaboration. Developing effective methods to assess the return on investment for such technologies is crucial for their successful implementation. Companies must also address potential workforce concerns related to job displacement by investing in retraining programs to equip employees with the skills necessary to work alongside robotic counterparts.

The projection by Nvidia’s CEO Jensen Huang that humanoids will become commonplace in manufacturing within the next five years underscores a significant shift towards advanced automation. Supported by technological advancements and strategic industry collaborations, humanoids are set to revolutionize manufacturing processes, offering solutions to labor shortages and enhancing operational efficiency. As this transformation unfolds, it will be imperative for industries to adapt to the changing landscape, ensuring that the integration of robots complements the human workforce and contributes to sustainable industrial growth.